2023/06/26

Foreign Customers Visit Ufine Lithium Battery Factory

As a leading lithium battery manufacturer in China, Ufine has professional technical personnel and professional production equipment. It is a comprehensive lithium battery manufacturer integrating R&D, design, and pack. It is located in Jiangmen, Guangdong Province.

Visit Ufine lithium battery factory

On 9th June 2023, a foreign customer visited Ufine. In our factory, we explained to our customers in detail the contents and control points of the various production processes, quality control, safety testing, and electrical performance laboratories.

Foreign customers visited the workshop environment and expressed satisfaction and praise for the clean and tidy working environment of Ufine.

Our sales representative showed customers around our factory and introduced how our batteries are made. The customer listened attentively and said “ I have never seen such a tidy workshop in China. This working condition is nice.” He expressed high recognition of our production management and quality control and is full of expectations for future cooperation.

In the production workshop, we first led customers to visit the storage and use of raw materials. We strictly controlled the quality of raw materials, and only raw materials that meet the standards could be used in the production process. At the same time, we set up a special storage area, classified the raw materials for storage, and took appropriate temperature and humidity control measures to ensure the stability and reliability of raw materials.

Lithium battery production process

Next, we introduced the various processes on the production line in detail.

Electrode Production

We precisely control the ratio and mixing time of various materials to ensure the performance and stability of the battery.

In the slurry coating process, we use high-precision equipment to evenly coat the slurry on the positive and negative electrodes of the battery to ensure the energy output balance and stability of the battery.

In the slurry coating process, we use high-precision equipment to evenly coat the slurry on the positive and negative electrodes of the battery to ensure the energy output balance and stability of the battery.

Electrode Creation

After coating, we will make the positive and negative electrodes with ca dating pass two big rolls for a smooth surface to increase surface density. The sheet of positive and negative electrodes will be split into strip to strip. Then the battery tab will be welded with the electrode.

The machine will wind the positive and negative electrodes and the diaphragm. The diaphragm separates the positive and negative electrodes. And this is LiPo battery inner cell warping.

Forming

The aluminum plastic film is stamped and molded using the fixed mold to prepare for the assembly of the battery cell.

In multiple production lines, the workers are busy assembling the battery cell, and the appearance of the battery cell basically present.

Electrolyte

Before injection, the cell needs to remove as much water as possible to avoid moisture remaining in the cell causing swelling. And these are our ovens.

The battery cell needs to be injected by the electrolyte to carry out sufficient diffusion movement of ions better.

Formation

The battery is charged to activate the active material inside the battery cell. The metal shell of the battery cell needs to be sealed again, and the air in the battery cell is drained, so that the internal of the battery cell is in a vacuum state to keep air tightness.

After the battery is fully charged, the electric discharge is going to proceed, so that the size of the electric capacity can be measured. Testing the K value of the battery cell to determine whether the K value of the battery cell is abnormal is important. The K value is the amount of power a battery loses each day.

Battery Pack

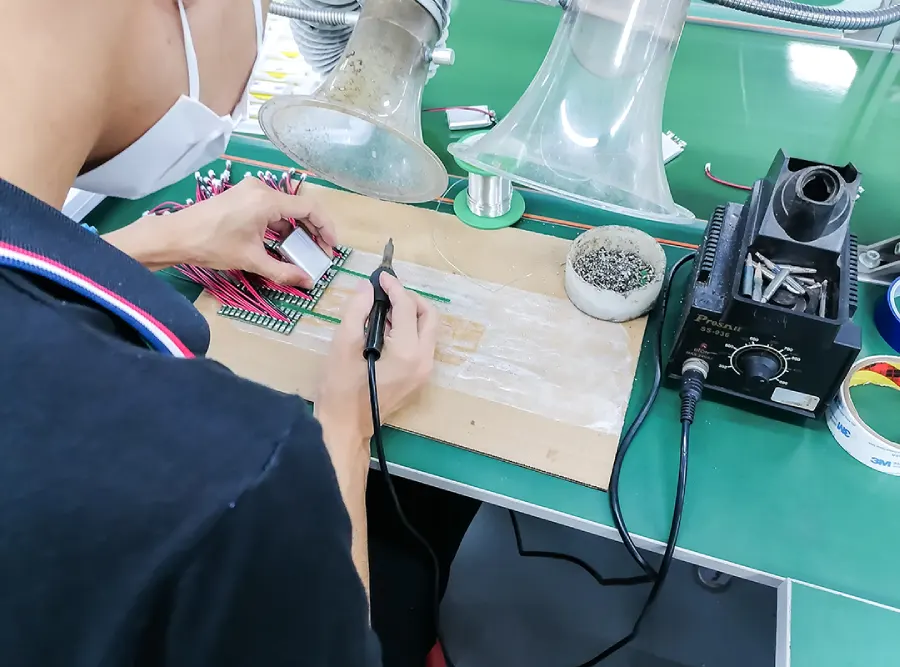

In most instances, a battery consists of a cell and a PCM(power control module). A single cell needs a protection board and wires to protect itself when it works. And this assembling process we call Pack.

Our employee is welding the battery cell to the protection board and wires.

Battery Testing

Ufine has been attaching great importance to the quality of our products. There are multiple kinds of battery testing for our product to assure the quality of our products such as Overcharge Test、Free fall Test、Thermal shock Test、Short-circuit Test、Impact Test、Crush Test and Nail penetrating Test. We are confident to keep and improve our product quality.

During the visit, the customer was very concerned about quality control and made some valuable suggestions. The customer suggested that we further strengthen the management and monitoring of raw material suppliers to ensure the stability and reliability of raw materials. They also stressed the need for strict quality control of every link in the production process to ensure product consistency and reliability. We attach great importance to our customer's suggestions and will take them seriously and make improvements.

Through this visit and communication, we have developed a good cooperatives highly appreciated and recognized Ufine's production management and quality control. We will continue to strive to improve product quality, strengthen technological innovation, and provide customers with better products and services. We look forward to future cooperation to jointly promote the development of the lithium battery industry.

If you are interested in our batteries, please contact us to learn more information about our products.

Media Contact

xiaotuanyuan@ufinebattery.com