Knowing the nuances of battery technology is essential for effective content optimization. This article will delve into the basics of the differences between a battery cell, a battery module, and a battery pack. Exploring their definitions, designs, characteristics, and applications can illuminate the complex ecosystem that drives modern technology.

Part 1. Battery cell

What is a battery cell?

It is the basic unit of a battery, responsible for storing and releasing electrical energy. A battery cell comprises three primary components: the positive electrode (anode), the negative electrode (cathode), and the electrolyte. These elements work in concert to facilitate the flow of ions between electrodes during the charging and discharging processes. This flow of ions generates electrical current, which can be harnessed to power various devices and applications. A battery cell is the fundamental building block that enables portable power solutions across multiple industries and technologies.

Battery Design

Size

Battery cells come in different sizes, ranging from miniature cells used in small electronics like watches to more giant cells employed in electric vehicles. The size of the cell impacts its capacity and energy density, dictating its suitability for specific devices or systems.

Shape

Battery cells can have diverse shapes, including cylindrical, prismatic, and pouch designs. Cylindrical cells, commonly found in flashlights and laptops, offer a compact form factor and efficient packaging. Prismatic cells, with their rectangular shape, are often used in devices where space optimization is essential, like smartphones and tablets. Pouch cells, characterized by their flexibility, are suitable for applications requiring unconventional shapes or custom configurations.

Internal Chemistry

The internal chemistry of a battery cell determines its performance characteristics, including voltage, capacity, and cycle life. Different chemistries, such as lithium-ion, nickel-metal hydride, and lead-acid, offer varying trade-offs in terms of energy density, cost, and safety. Lithium-ion cells, for instance, are known for their high energy density and lightweight construction, making them ideal for portable electronics and electric vehicles.

Electrode Materials

The choice of electrode materials significantly influences a battery cell’s overall performance and longevity. Common electrode materials include lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), and nickel manganese cobalt oxide (NMC). Each material has unique energy density, stability, and safety characteristics, allowing manufacturers to tailor cells to specific application requirements.

Packaging and Encapsulation

Battery cells are typically encased in protective packaging to safeguard against physical damage and environmental factors. The packaging material should provide adequate insulation and sealing to prevent leakage of electrolytes and ensure long-term reliability. Additionally, proper encapsulation helps mitigate safety risks associated with thermal runaway or short circuits.

Battery Applications

- Consumer Electronics: Battery cells power devices like smartphones, tablets, and laptops, enabling portable usage and on-the-go convenience.

- Electric Vehicles (EVs): Battery cells are crucial for EVs, providing the energy needed for propulsion and driving the shift towards sustainable transportation.

- Energy Storage Systems: Battery cells contribute to energy storage systems, storing excess energy from renewable sources like solar and wind for later use, enhancing grid stability and resilience.

- Portable Power Banks: Battery cells are used in power banks, offering convenient backup power for smartphones, tablets, and other mobile devices when the main power is unavailable.

- Medical Devices: Battery cells power various medical devices, such as portable monitors and infusion pumps, ensuring reliable operation and patient care in clinical settings.

Part 2. Battery control module

What does the battery control module do?

A Battery Control Module (BCM) is a crucial component within a battery management system that serves as an intermediary between individual battery cells and the overall battery pack. It actively monitors and regulates each cell’s performance, safety, and state of charge, ensuring optimal operation and coordination within the battery pack. The BCM plays a pivotal role in maximizing the efficiency, longevity, and safety of the entire battery system, facilitating seamless integration into various applications such as electric vehicles and energy storage systems.

Battery Design

Mechanical Support

The BCM is typically housed in a sturdy casing to provide mechanical support and protection to its internal components. This casing may incorporate features such as mounting brackets or heat sinks to enhance stability and dissipate heat generated during operation.

Thermal Management

Thermal management is critical in designing a BCM to maintain optimal operating temperatures and prevent battery pack overheating. Heat sinks, thermal pads, or active cooling systems like fans or liquid cooling may be integrated into the BCM to manage thermal loads effectively.

Electrical Interconnects

The BCM features electrical interconnects to establish connections with individual battery cells and external control systems. These interconnects may include wiring harnesses, connectors, or busbars designed to facilitate reliable communication and power distribution between the BCM and other components of the battery management system.

Sensor Integration

The BCM incorporates various sensors, such as voltage, temperature, and current sensors, to monitor the performance and health of each battery cell. These sensors provide real-time data to the BCM, enabling it to make informed decisions regarding charging, discharging, and safety protocols.

Microcontroller Unit (MCU)

The BCM’s heart is a microcontroller unit (MCU) responsible for processing sensor data, executing control algorithms, and interfacing with external systems. The MCU is central in implementing battery management strategies, including state-of-charge estimation, cell balancing, and fault detection.

Battery Applications

- Automotive Applications: Battery control modules are extensively used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to monitor and manage the performance of battery packs, ensuring optimal efficiency and longevity of the vehicle’s powertrain.

- Grid Storage: Battery control modules play a crucial role in grid storage systems, where they oversee the charging, discharging, and balancing of large-scale battery arrays used for renewable energy integration, grid stabilization, and peak load management.

- Marine Propulsion Systems: In marine applications, such as electric propulsion systems for ships and boats, battery control modules regulate the operation of battery packs, optimizing power delivery and ensuring safe and efficient propulsion.

Part 3. Battery pack

What is a battery pack?

A battery pack is a collection of individual cells or modules arranged in a specific configuration to provide a unified power source. These cells or modules are typically interconnected and housed within a protective enclosure, ensuring safe and efficient operation. The arrangement of cells or modules within the lithium-ion battery pack is carefully designed to optimize performance, capacity, and voltage output for the intended application. Battery packs are commonly used in various devices and systems, including electric vehicles, portable electronics, and energy storage systems, to deliver reliable and consistent power supply.

Battery Design

Battery Cell Arrangement:

- Determine the required voltage and capacity for the application.

- Select the appropriate type and size of battery cells (e.g., lithium-ion, lithium-polymer) based on the performance requirements.

- Decide on the arrangement of cells, including series and parallel configurations, to achieve the desired voltage and capacity.

- Ensure uniformity in cell specifications and characteristics to maintain balance and consistency in the pack.

Housing Design:

- Choose suitable materials for the battery pack housing that provide adequate strength, durability, and thermal management.

- Design the housing to accommodate the arrangement of battery cells and modules, ensuring efficient use of space.

- Incorporate features such as cooling vents, heat sinks, or thermal insulation to regulate temperature and prevent overheating.

- Implement measures to protect the battery cells from physical damage, moisture, dust, and other environmental factors.

Safety Features:

- Integrate a Battery Management System (BMS) to monitor and manage the charging and discharging process, cell balancing, and temperature control.

- Include built-in protections against overcharging, over-discharging, short circuits, and thermal runaway.

- Install safety devices such as fuses, circuit breakers, or disconnect switches to isolate the battery pack in emergencies.

- Ensure compliance with safety standards and regulations, such as UN/DOT transportation regulations and UL certifications.

Electrical Connections:

- Design the electrical connections between battery cells, modules, and external terminals with low resistance to minimize energy loss and maximize efficiency.

- Use high-quality conductive materials and connectors that provide reliable and secure connections, reducing the risk of voltage drops or electrical faults.

- Implement proper insulation and shielding to prevent electrical arcing, corrosion, and electromagnetic interference.

Testing and Validation:

- Conduct thorough testing of the battery pack design to verify performance, safety, and reliability under various operating conditions.

- To assess durability and endurance, perform stress tests, including temperature cycling, vibration, shock, and electrical load testing.

- Validate compliance with industry standards and customer requirements through rigorous testing protocols and certification processes.

Battery Applications

- Portable Electronic Products: Battery packs are widely used in mobile electronic devices such as smartphones, tablets, and laptops, providing convenient and on-the-go power solutions for consumers.

- Electric Vehicles (EVs): Battery packs serve as electric vehicles’ primary energy storage system, supplying the power needed for propulsion and enabling emission-free transportation.

- Stationary Energy Storage Solutions: Battery packs are deployed in stationary energy storage systems to store excess energy generated from renewable sources like solar and wind, providing backup power, grid stabilization, and load-shifting capabilities.

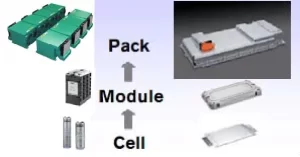

Part 4. Battery cell vs battery module vs battery pack: What is the difference?

Battery Cell

A battery cell is the basic building block of a battery, consisting of electrodes, electrolytes, and a casing. It is the smallest unit capable of storing and releasing electrical energy through chemical reactions.

Battery Module

A battery module is a collection of interconnected cells housed within a single enclosure. It typically includes cooling systems, voltage monitoring circuits, and structural support elements. Battery modules allow for scalability and customization of battery packs by combining multiple cells to meet specific energy and power requirements.

Battery Pack

A battery pack, also known as a battery pack or battery assembly, comprises one or more battery modules or cells arranged in series or parallel configurations. It integrates components such as battery management systems (BMS), thermal management systems, and safety features to provide a complete power solution for a specific application. Battery packs are commonly used in electric vehicles, energy storage systems, and portable electronics, offering higher voltage, capacity, and energy density than individual cells or modules.

Part 5. FAQs

-

What is the difference between a battery module and a battery pack?

A battery module is a group of individual battery cells connected, usually with their management system. On the other hand, a battery pack consists of one or more modules, along with additional components like casing, connectors, and thermal management systems. -

What is a cell in a battery pack?

A cell in a battery pack refers to the individual battery unit that stores and releases electrical energy. These cells are typically cylindrical or prismatic in shape. They are connected in series or parallel to achieve the desired voltage and capacity for the pack. -

What is a modular battery pack?

A modular battery pack is a battery pack design that consists of multiple interchangeable modules. These modules can be easily replaced or upgraded, offering flexibility and scalability in capacity and configuration. -

What is a cell vs pack vs module?

A cell is the basic unit of a battery, while a module is a group of cells connected. On the other hand, a pack includes one or more modules and additional components necessary for operation, such as casing, connectors, and control electronics. -

What is the difference between a pack and a module?

The main difference between a pack and a module is their scale and complexity. A module is a smaller unit consisting of interconnected cells. At the same time, a pack is a larger assembly that includes one or more modules along with additional components for functionality and safety.

Related Tags:

More Articles

Overview of Deep Cycle Lithium Battery

In this article, we explore the life, voltage, capacity, and charging considerations of deep cycle lithium batteries.

How Long do Lithium Batteries Last?

How long do lithium batteries last? we will explore the factors that influence the lifespan of lithium batteries and provide insights into their longevity.

How to Choose the Best LiFePO4 Battery?

Choose LiFePO4 batteries for superior performance, safety, and versatility in EVs, UPS, and backup power. This guide helps you make informed decisions.

Get 12v Lithium Car Battery As a Power Source for the Ride

Make the right choice for your vehicle's battery needs by installing a 12 volt lithium car battery. You will enjoy maintenance-free longevity with this change.

Everything About A Small Lithium Ion Battery

Discover the features, uses & future potential of a small lithium ion battery. A compact and tiny powerhouse ideal for smartphones, wearables, drones & more.