Part 1. What are lithium batteries in parallel and series?

The voltage and capacity of a single lithium battery cell are limited. In actual use, lithium batteries need to be combined in parallel and series to obtain a lithium battery pack with a higher voltage and capacity to meet the actual power supply needs of the equipment.

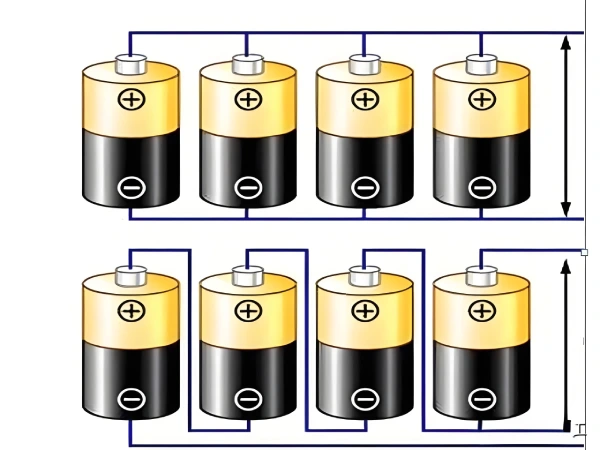

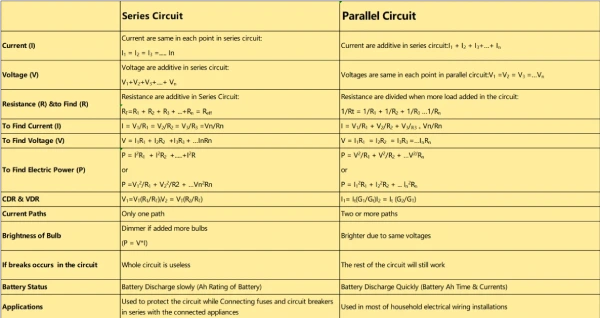

- Lithium batteries in series: The voltages are added, the capacity remains unchanged, and the internal resistance increases.

- Lithium batteries in parallel: The voltage remains unchanged. The capacities are added. The internal resistance is reduced. The power supply time is extended.

- Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases the voltage and capacity.

- Lithium battery series voltage: 3.7 V cells can be assembled into a battery pack with a 3.7*(N) V (N: number of cells) as needed. Such as 7.4V, 12V, 24V, 36V, 48V, 60V, 72V, etc.

- Lithium battery parallel capacity: 2000mAh lithium battery cells can be assembled into a battery pack with a capacity of 2*(N)Ah as needed (N: number of cells). Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah, etc.

The difference between lithium batteries in parallel and series

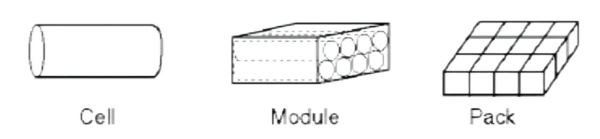

Part 2. Lithium battery pack

Lithium battery pack refers to the processing, assembling, and packaging of lithium battery packs. The process of assembling lithium batteries into groups is called PACK, which can be a single battery or a series-parallel lithium battery pack.

Lithium battery packs usually consist of a plastic shell, protective plate, battery core, output electrode, connection bumper, other insulating tape, double-sided tape, etc.

- Lithium cell: The core part of lithium battery.

- PCB: It plays the functions of overcharge, over-discharge, over-current, short-circuit, NTC temperature control intelligent protection, etc.

- Plastic shell: the supporting frame of the entire battery; positioning and fixing the protective plate; carrying and limiting all other non-shell parts.

- Terminal leads: Various terminal wire charging and discharging interfaces can be provided for use in various electronic products, energy storage products, and backup power supplies.

- Nickel sheet/bracket: battery core connection and fixing components

Part 3. How to calculate the number of series and parallel lithium battery packs?

The voltage of lithium batteries increases when connected in series, and the capacity increases when connected in parallel. So how to calculate how many series and parallels a lithium battery pack consists of, and how many cells it consists of?

Before calculation, we need to know the specifications of the cells from which this lithium battery pack is assembled. Because different lithium battery cells have different voltage capacities. The number of series and parallel required is different to assemble a lithium battery pack of specific specifications.

Common lithium cell types include 3.7V lithium cobalt oxide cells, 3.6V ternary cells, 3.2V lithium iron phosphate cells, and 2.4V lithium titanate cells. The capacity of lithium batteries varies depending on cell size, materials, and manufacturers.

Take the 48V 20mAh lithium battery pack as an example:

Assume that the single cell used is 18650 3.7V 2Ah

Number of cells connected in parallel: 20Ah/2Ah=10, that is, 10 cells connected in parallel

Number of cells in series: 48V/3.7=13, that is, 13 cells in series

The entire lithium battery pack: 13×10=130 cells

Part 4. Lithium batteries in series of different voltages

Due to the consistency problem of lithium batteries, when lithium batteries are connected in parallel or in series under the same system (such as ternary batteries or LiFePo4 batteries), it is also necessary to select lithium batteries with the same voltage, internal resistance, and packing capacity.

Connecting lithium batteries with different voltages and internal resistances in series will cause a certain lithium battery to be fully charged first and discharged first in each cycle. If the lithium battery has a PCB and does not fail, it will only cause the capacity of the entire set to decrease. However, suppose the lithium battery does not have a PCB. In that case, it may cause the battery to be overcharged, over-discharged, or even damaged.

Part 5. Lithium batteries in parallel with different capacities

If different capacities or old and new lithium batteries are mixed, leakage, zero voltage, etc. may occur. This is due to the difference in capacity during the charging process, which causes some lithium batteries to be overcharged during charging. Some lithium batteries are not fully charged. Some lithium batteries with high capacity are not fully discharged during discharge, while those with low capacity are over-discharged. In such a vicious cycle, the lithium battery will be damaged and produce leakage or low (zero) voltage.

Part 6. Should the lithium battery pack be connected in parallel or in series first?

Typical connection methods to form a lithium battery pack include parallel connection first and then series connection, first series connection, then parallel connection, and mixed connection.

For example, lithium battery packs for pure electric buses are usually connected in parallel first and then in series. Lithium battery packs used for grid energy storage often adopt a serial connection first and then a parallel connection.

Advantages of lithium batteries first in parallel and then in series

The lithium battery cell will automatically exit after failure. In addition to the battery capacity being reduced, it will not affect its use after a parallel connection;

When a certain lithium battery cell in a parallel connection is short-circuited, the parallel circuit current will be very large. However, it is usually avoided by adding fuse protection technology.

Disadvantages of lithium batteries first in parallel and then in series

Due to differences in the internal resistance of lithium battery cells and uneven heat dissipation, the cycle life of lithium battery packs after parallel connection will be affected.

Advantages of lithium batteries in series first and then in parallel

If the lithium batteries are connected in series first and then in parallel, the failure probability of the large-capacity lithium battery pack is reduced. Stringing first and then paralleling is very helpful for the consistency of the lithium battery pack.

From the perspective of the reliability of lithium battery pack connection and the development trend and performance impact of voltage inconsistency, the first parallel and then series connection method is better than the first series and then parallel connection method. The lithium battery topology of serial first and then parallel is conducive to detecting and managing each lithium battery cell in the system.

Part 7. Lithium battery series and parallel charging

1. Lithium battery charging in series

At present, lithium battery packs are generally charged in series. This is mainly because the series charging method has a simple structure, low cost, and is easier to implement.

However, due to the differences in capacity, internal resistance, attenuation characteristics, self-discharge, and other performances between lithium battery cells. When charging lithium battery packs in series, the single cell with the smallest capacity in the battery pack will be fully charged first.

At this time, the other batteries are not fully charged. If series charging continues, a single fully charged cell may be overcharged. Overcharging lithium batteries will seriously damage the battery’s performance and may even explode.

Therefore, in order to prevent overcharging of a single lithium cell, lithium battery packs are generally equipped with a battery management system (BMS). Each cell is protected from overcharging through BMS.

During series charging, if the voltage of a single cell reaches the overcharge protection voltage, the battery management system will cut off the entire series charging circuit and stop charging. This will prevent this single-cell battery from being overcharged, which will cause other lithium batteries to be unable to be fully charged.

2. Lithium battery charging in parallel

Each lithium battery cell should ensure balanced charging when lithium batteries are charged in parallel. Otherwise, the performance and life of the entire lithium battery pack will be affected during use.

Commonly used equalizing charging technologies include:

- Constant shunt resistor balanced charging

- On-off shunt resistor balanced charging

- Average battery voltage equalization charge

- Switched capacitor equalization charging

- Buck converter equalization charging

- Inductor equalization charging.

There are several issues you need to pay attention to when charging lithium batteries in parallel:

Lithium batteries with and without PCBs cannot be charged in parallel. Batteries without protective plates are easily damaged by overcharging.

Batteries charged in parallel usually need to remove the PCB that comes with the battery and use a battery protection board.

If the battery is charged in parallel without a lithium battery PCB, the charging voltage must be limited to 4.2V. Moreover, a 5V charger cannot be used.

When lithium batteries are connected in parallel, there will be a charging protection chip to protect the lithium batteries from charging. Lithium battery manufacturers have fully considered the changing characteristics of lithium batteries after parallel connection when making parallel lithium batteries and have also carried out current design and cell selection in accordance with the above requirements. Therefore, users need to charge the battery step by step according to the instructions for parallel lithium batteries to avoid possible damage to the battery caused by incorrect charging.

Part 8. Precautions for lithium batteries parallel and series

- Do not use lithium batteries of different brands together.

- Do not use lithium batteries of different voltages together.

- Do not mix different capacities or old and new lithium batteries.

- Batteries of different chemical materials cannot be mixed, such as nickel metal hydride and lithium batteries.

- Replace all batteries when they are low on charge.

- Use a lithium battery protection board with corresponding parameters.

- Choose a battery with consistent performance. The use of lithium batteries in series and parallel requires pairing lithium battery cells. Pairing standards: voltage difference ≤10mV, internal resistance difference ≤5mΩ, capacity difference ≤20mA.

Part 9. Lithium battery charging precautions

- Lithium batteries must use a special charger; otherwise, they may not reach saturation and affect their performance.

- Lithium batteries do not need to be fully discharged before charging.

- Do not leave the charger plugged into the socket for a long time. Remove the battery from the charger as soon as possible after it is fully charged.

- Batteries should be removed from electrical appliances that have not been used for a long time, and the batteries should be drained and stored.

- Do not insert the positive and negative terminals of the battery reversely; otherwise, the battery may bulge or rupture.

- Nickel battery chargers and lithium battery chargers cannot be mixed.

Related Tags:

More Articles

Overview of Deep Cycle Lithium Battery

In this article, we explore the life, voltage, capacity, and charging considerations of deep cycle lithium batteries.

How Long do Lithium Batteries Last?

How long do lithium batteries last? we will explore the factors that influence the lifespan of lithium batteries and provide insights into their longevity.

How to Choose the Best LiFePO4 Battery?

Choose LiFePO4 batteries for superior performance, safety, and versatility in EVs, UPS, and backup power. This guide helps you make informed decisions.

Get 12v Lithium Car Battery As a Power Source for the Ride

Make the right choice for your vehicle's battery needs by installing a 12 volt lithium car battery. You will enjoy maintenance-free longevity with this change.

Everything About A Small Lithium Ion Battery

Discover the features, uses & future potential of a small lithium ion battery. A compact and tiny powerhouse ideal for smartphones, wearables, drones & more.